26th November 2016 COILED TUBING DRILLING

Author: Toni Miszewski

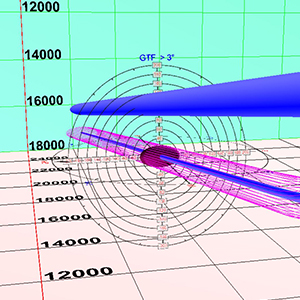

A direct measurement of downhole WOB is vital for accurate control of the drilling process during Coiled Tubing Drilling (CTD). Without it, motor stalls will be more frequent and directional control will be more difficult.

In a vertical well with conventional jointed pipe drilling it is a reasonable assumption that the weight applied to the drill bit is directly related to the hook load at surface. This assumption starts to become less valid as soon as the well becomes deviated or horizontal because of the friction between the pipe and the wellbore. But even then, it is possible to compare upward and downward loads to estimate the friction and therefore determine WOB.

With Coiled Tubing Drilling (CTD) the situation is complicated further such that the assumption that surface load is directly linked to downhole WOB definitely cannot hold.. . .

We want to provide a source of useful information to help you do your job and provide general interest. From working in the upstream O&G industry for almost 25 years, we wanted to find a platform to informally share our insights and experience in the hope of inspiring more people to actively take part and learn more about a fascinating industry

SEND

Sign up here:

Popular Posts

To keep up to date, enter your email address here

. . . from the team at AnTech

1

2

3

4

5

© AnTech 2016. All rights reserved.

+44 1392 933 100 | +1 800-868-1562